一、Implement Steps

1.1 Matrix Calculation

- Calculate mass matrix M(1)

- Calculate the stiffness matrix of each suspension k(2)

- Calculate angle transpose matrix T(4)

- Calculate position transition matrix B(3)

- Accumulative calculation of stiffness matrix K(5)

M=\begin{bmatrix}

m&0&0&0&0&0\\

0&m&0&0&0&0\\

0&0&m&0&0&0\\

0&0&0&I_{xx}&-I_{xy}&-I_{xz}\\

0&0&0&-I_{xy}&I_{yy}&-I_{yz}\\

0&0&0&-I_{xz}&-I_{yz}&I_{zz}\\

\end{bmatrix}\tag{1}

k_i=\begin{bmatrix}

k_{ui}&0&0\\

0&k_{vi}&0\\

0&0&k_{wi}\\

\end{bmatrix}\tag{2}B_i=\begin{bmatrix}

1&0&0&0&Z_i&-Y_i\\

0&1&0&-Z_i&0&X_i\\

0&0&1&Y_i&-X_i&0\\

\end{bmatrix}\tag{3}T_i=\begin{bmatrix}

cos\alpha_{ui}&cos\beta_{ui}&cos\gamma_{ui}\\

cos\alpha_{vi}&cos\beta_{vi}&cos\gamma_{vi}\\

cos\alpha_{wi}&cos\beta_{wi}&cos\gamma_{wi}\\

\end{bmatrix}\tag{4}K=\sum_{i=1}^nB_i^\mathrm{T}T_i^\mathrm{T}K_iB_iT_i\tag{5}(3)According to provided conditions, if it is not relative to the center position, it may be the following expression(From the content in reference [3] ,but is not provided in the program)

B_i=\begin{bmatrix}

1&0&0&0&Z_i-Z_0&Y_0-Y_i\\

0&1&0&Z_0-Z_i&0&Y_i-Y_0\\

0&0&1&Y_i-Y_0&X_0-X_i&0\\

\end{bmatrix}\tag{3-2}(4)There is another form of expression, with only two angles(From the content in reference [1] ,but is not provided in the program)

T_i=\begin{bmatrix}

cos\theta_{1i}&0&sin\theta_{1i}\\

sin\theta_{1i}\theta_{2i}&cos\theta_{2i}&-cos\theta_{1i}cos\theta_{2i}\\

-sin\theta_{1i}&sin\theta_{2i}&cos\theta_{1i}cos\theta_{2i}\\

\end{bmatrix}\tag{4-2}1.2 Nature frequency and mode of vibration

- Calculate the matrix from M and K, take the eigenvalues, and use ω=2πf to obtain the natural frequency f.

- [v,d]=eig to solve the mode of vibration

二、Code

clc;

clear;

%Create parameter variables:

% Number of suspensions

num=4;

% Mass(kg)

m=277.33;

%Create parameter array

% Inertial parameters(xx,yy,zz,xy,yz,zx)

aj=[16.87,7.92,16.55,-2.47,2.95,-0.95];

% Suspension position(x1,y1,z1;x2,y2,z2;x3,y3,z3...)

al=[-9.3,209.5,-136.5;20.5,-436.3,-156.5;-359.2,12.5,164.5;584.9,37.1,239.5]'*10^-3;

% Initial dynamic stiffness value

ak=[120,35,100;155,90,150;100,70,110;80,42,115]'*10^3;

% Initial angle value (if there are more than three, add them to the array, and multiply by cos in following precedure)

aa{1}=[0,90,90;90,0,90;90,90,0];

aa{2}=[0,90,90;90,0,90;90,90,0];

aa{3}=[0,90,90;90,0,90;90,90,0];

aa{4}=[0,90,90;90,0,90;90,90,0];

%Calculate mass matrix

M=[diag([m,m,m]),zeros(3);zeros(3),[aj(1),-aj(4),-aj(6);-aj(4),aj(2),-aj(5);-aj(6),-aj(5),aj(3)]];

%Calculate stiffness matrix

% Calculate intermediate parameters

for i=1:num

%Calculate ki

K{i}=diag([ak(1,i),ak(2,i),ak(3,i)]);

%Calculate Bi

B{i}=[eye(3),[0,al(3,i),-al(2,i);-al(3,i),0,al(1,i);al(2,i),-al(1,i),0]];

%计算Ti

T{i}=cosd(aa{i});

end

% Calculate stiffness matrix K

Ks=0;

for i=1:num

Ks=Ks+B{i}'*T{i}'*K{i}*T{i}*B{i};

end

%Calculate the natural frequency and mode of vibration

A=(inv(M))*Ks;

[V,E1]=eig(A);

f=diag(sqrt(E1)/(2*pi));

[f,Sort]=sort(f);

f

V1=V(:,Sort);

v1三、Correctness Verification

Data:

Table 1 Mass and inertia parameters of powertrain (kg,kg·m²)

| m | $I_x$ | $I_y$ | $I_z$ | $I_xy$ | $I_yz$ | $I_zx$ |

|---|---|---|---|---|---|---|

| 227.33 | 16.87 | 7.92 | 16.55 | -2.47 | 2.95 | -0.95 |

The above data can be measured using a three wire pendulum during the experiment.

Table 2 Initial position of suspension (mm)

| Position | Front suspension | Back suspension | Left suspension | Right suspension |

|---|---|---|---|---|

| x | -9.3 | 20.5 | -359.2 | 584.9 |

| y | 209.5 | -436.3 | 12.5 | 37.1 |

| z | -136.5 | -156.5 | 164.5 | 239.5 |

Table 3 Initial stiffness (N/mm)

| Position | Front suspension | Back suspension | Left suspension | Right suspension |

|---|---|---|---|---|

| $K_u$ | 120 | 155 | 100 | 80 |

| $K_v$ | 34 | 90 | 70 | 42 |

| $K_s$ | 100 | 150 | 110 | 115 |

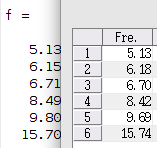

Run the above code in MATLAB 2020a and output the following results:

f =

5.133572625279529

6.154126964783480

6.715844929048983

8.495706155632371

9.802800097989474

15.708570201117141

V1 =

-0.002575595333373 0.039466990231208 0.604485422397946 -0.042057586371625 0.092059939681550 -0.001923323097360

-0.984141131745956 0.022430044492999 -0.005879380718305 0.005788641434482 0.002382522157190 -0.000381130252290

-0.031125123189836 -0.314088774322631 0.080306281140817 0.217013382019956 0.029371516378800 0.011868177386655

-0.172570999898838 -0.903582353870596 0.091580682327157 -0.951268659010678 -0.213972175366066 0.203700986952554

-0.024014007619249 -0.245061865768309 0.069605796709097 -0.017779503634877 -0.102534614271487 -0.955297284911824

0.011550032591457 -0.150900971999743 -0.784143940797264 -0.214183731216263 0.966622556205327 -0.213935287617928Use a software to calculate result and compare with the data calculated by MATLAB script.

It can be observed that the calculation results are approximate.

References:

[1]曾令贤.用MATLAB计算发动机悬置系统的固有频率和主振型[J].汽车科技,2005(04):27-29.

[2]王星. 电动汽车动力总成悬置系统优化设计[D].合肥工业大学,2015.

[3]薛华,刘志强,刘岩,苏迎.基于Matlab的动力总成悬置系统解耦优化[J].噪声与振动控制,2015,35(02):65-68.

I am a beginner and cannot guarantee the accuracy of calculations. Thanks!

This is a translated copy of my post “使用MATLAB计算动力总成悬置系统固有频率和主振型”, release in April 26, 2022.

Recent Comments